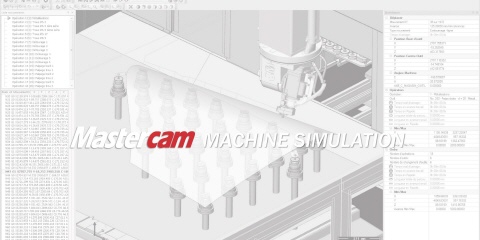

Post-Pro 5 axes

Elément essentiel et incontournable d'une CFAO, le post-processeur est le maillon final pour la bonne réalisation de vos pièces. |

Nos post-processeurs sont réalisés suivant vos habitudes et selon les spécificités de vos armoires ( Fanuc, NUM, Siemens, Heidenheim, etc..). |

Exemple de fichier ISO

%

O0012 (ROTOR-158X)

N10 (DESSIN: M:\client\5AXE.MCX)

N20 (OUTILS UTILISES)

N30 ( T1 FRAISE A CHANFREINER D=6. NBR-DENTS=4 A=15. )

N40 G40 G90 G80

N50 T1 D1 M6

N60 G0 G54 G90 G40 G80 S2500 M3

N70 G43 H1 Z200 M8

N80 G17

N90 M11

N100 (USINAGE 4 AXES CONTINUE)

N110 (ATTENTION L'OPERATION SOURCE EST DE TYPE 5 AXES)

N120 X-14.451 Y0. Z16.235 A-41.913

N130 G1 X-11.127 Y0. Z12.5 A-41.913 F500

N140 X-13.038 Y0. Z12.643 A-39.313 F200

-----------------------------------------------

-------------------------------------------

N480 X-22.225 Y0. Z11.449 A43.181

N490 X-23.886 Y0. Z12.006 A47.898

N500 X-25.202 Y0. Z12.5 A51.313

N510 X-29.682 Y0. Z14.722 A51.313 F1000

N520 G0 X-43.12 Y0. Z21.387 A51.313

N530 A0

N540 M10

N550 M9

N560 G17

N570 M30

Exemple num 1060 5 axes avec renvoi d'angle

%1003.

(ETABLI LE 26-04-11 A 18:11 H)

(PROG PAR PIERRE BOURNERIE )

( T51 )

N5 (USINAGE AVEC OUTIL T51 )

N10 G90 G17 G40 G80 G0 G94

N15 E60001=0

N20 E61001=0

N25 E62001=0

N30 E64001=E61001

N35 E80004=-522875.

N40 M9

N45 M5

N50 M151

N55 M170

N60 ( Outil renvoi angle 51 )

N65 M6 T50 D51

N70 M150

N75 M3 M40 S764

N80 ( PAS DE CLOCHE )

N85 E53051=0

N90 M3 M40 S764

N95 ( G81 - RA - P SECUR )

N100 Z1500.

N105 G151 EC0. EA0. EU0. EV0. EW0.

N110 G0 X0. Y0. C180. A-90.

N115 Z213.5

N120 G0 X0. Y0. Z173.5

N125 G1 X0. Y0. Z161.5 F305

N130 G0 X0. Y0. Z173.5

N135 G0 X0. Y0. Z213.5

N140 G0 X10. Y0. Z213.5 C180. A-90.

-------------------------------------------

N280 G0 X0. Y20. Z173.5

N285 G0 X0. Y20. Z213.5

N290 G0 X10. Y20. Z213.5 C180. A-90.

N295 G0 X10. Y20. Z173.5

N300 G1 X10. Y20. Z161.5 F305

N305 G0 X10. Y20. Z173.5

N310 G0 X10. Y20. Z213.5

N315 G0 X20. Y20. Z213.5 C180. A-90.

N320 G0 X20. Y20. Z173.5

N325 G1 X20. Y20. Z161.5 F305

N330 G0 X20. Y20. Z173.5

N335 G0 X20. Y20. Z213.5

N340 G151 EC0. EA0. EU0. EV0. EW0

N345 G0 Z1500.

N350 M3 M40 S764

N355 G151 EC0. EA0. EU0. EV0. EW0.

N360 ( G85 - RA - P SECUR )

N365 Z1500.

N370 G151 EC0. EA0. EU0. EV0. EW0.

N375 G0 X0. Y0. C180. A-90.

N380 Z213.5

N385 G0 X0. Y0. Z173.5

N390 G1 X0. Y0. Z161.5 F305

N395 G1 X0. Y0. Z173.5

------------------------------------

N555 G0 X10. Y20. Z213.5 C180. A-90.

N560 G0 X10. Y20. Z173.5

N565 G1 X10. Y20. Z161.5 F305

N570 G1 X10. Y20. Z173.5

N575 G0 X10. Y20. Z213.5

N580 G0 X20. Y20. Z213.5 C180. A-90.

N585 G0 X20. Y20. Z173.5

N590 G1 X20. Y20. Z161.5 F305

N595 G1 X20. Y20. Z173.5

N600 G0 X20. Y20. Z213.5

N605 G151 S0

N610 G0 Z1500.

N615 E53051=0

N620 M09

N625 M05

N630 M151

N635 E60001=0

N640 E61001=0

N645 E62001=0

N650 E64001=E61001

N655 E80004=-130000.

Mazak toute version

%

O0001 (O1234)

N100 (POST-PRO FICAM)

N102 (MACHINE - MAZAK FUSION-640)

N104 (DESSIN MASTERCAM - T)

N106 (PROG-CN DU 20-12-11 A 11:15)

N108 (LISTE DES OUTILS UTILISES)

N110 (T3 FRAISE 2 TAILLES DIAM=4. 4 DENTS ARS)

N112 (FIN DE LISTE DES OUTILS)

N114 G0 G90 G40 G80 G98 G17

N116 G91 G28 Z0

N118 (*GROUPE D'USINAGES-1*)

N120 T3 M6

N122 (T3 FRAISE 2 TAILLES DIAM=4. 4 DENTS ARS)

N124 (CORRECTION ORDINATEUR GAUCHE)

N126 (SUREP R 0. SUREP Z 0.)

N128 G40 G80 G90 G17 G54

N130 S9549 M3

N132 G0 X5.3 Y6.105

N134 G43 Z50. H0

N136 Z2.

N138 G1 Z0. F1910

N140 X5.301 F3820

N142 X5.303

N144 X5.304

N146 X5.305 Y6.106

N148 N

N150 Y6.059

N152 Y6.056

N154 X5.197 Y6.053

N156 X5.198 Y6.05

N158 Y6.047

N160 X5.199 Y6.044

N162 X5.2 Y6.041

N164 X5.201 Y6.039

N166 X5.202 Y6.036

N168 X5.203 Y6.033

N170 X5.204 Y6.03

N172 X5.205 Y6.027

N174 X5.207 Y6.024

N176 X5.208 Y6.022

N178 X5.21 Y6.019

N180 X5.211 Y6.016

N182 X5.213 Y6.013

N184 X5.215 Y6.011

N186 X5.216 Y6.008

N188 X5.218 Y6.006

N190 X5.22 Y6.003

N192 X5.222 Y6.

N194 X5.224 Y5.998

N196 X5.227 Y5.995

N198 X5.229 Y5.993

N200 X5.231 Y5.991

N202 X5.234 Y5.988

N204 X5.236 Y5.986

N206 X5.239 Y5.984

N208 X5.241 Y5.982

N210 X5.244 Y5.98

N212 X5.247 Y5.978

N214 X5.25 Y5.976

N216 G3 X5.874 Y4.56 I1.43 J-.28

N218 G3 X6.782 Y7.217 I-.483 J1.649

N220 G3 X3.537 Y7.167 I-1.605 J-1.161

N222 G3 X4.826 Y3.694 I1.878 J-1.278

N224 G3 X8.056 Y6.163 I.67 J2.471

N226 G3 X4.366 Y8.913 I-2.865 J.007

N228 G3 X2.514 Y4.317 I.915 J-3.04

N230 G3 X7.942 Y3.495 I3.038 J1.724

N232 G3 X7.465 Y9.409 I-2.609 J2.766

N234 G3 X1.293 Y7.465 I-2.315 J-3.422

N236 G3 X4.901 Y1.445 I4.167 J-1.594

N238 G3 X10.286 Y6.603 I.603 J4.76

N240 G3 X9.558 Y8.837 I-4.78 J-.323

N242 G3 X9.459 Y8.94 I-.768 J-.641

N244 G2 X8.54 Y9.91 I5.757 J6.375

N246 G3 X3.618 Y11.074 I-3.441 J-3.561

N248 G3 X.359 Y8.263 I1.523 J-5.06

N250 G3 X.326 Y7.84 I.958 J-.288

N252 G2 X.192 Y5.51 I-6.148 J-.817

N254 G3 X.856 Y2.699 I4.02 J-.535

N256 G3 X5.332 Y.214 I4.588 J2.99

N258 G3 X5.947 Y.502 I-.171 J1.165

N260 G1 X6.111 Y.617

N262 X10.234 Y3.513

N264 G3 X11.341 Y5.556 I-2.44 J2.643

N266 G3 X11.353 Y7.379 I-4.691 J.944

N268 G3 X10.87 Y7.954 I-.951 J-.309

N270 G2 X7.824 Y11.101 I3.316 J6.256

N272 G3 X6.265 Y12.19 I-2.373 J-1.738

N274 G3 X2.524 Y11.957 I-1.563 J-5.048

N276 G3 X.119 Y10.155 I2.286 J-5.557

N278 G3 X.042 Y9.234 I.969 J-.545

N280 G1 X.085 Y9.038

N282 G2 X.361 Y7.512 I-11.001 J-2.783

N284 G1 X.389 Y7.346 Z.033

N286 X.444 Y7.187 Z.065

N288 X.525 Y7.04 Z.098

N290 X.629 Y6.883 Z.134

N292 X.663 Y6.832 Z.146

N294 X.694 Y6.754 Z.163

N296 X.69 Y6.67 Z.179

N298 X.651 Y6.595 Z.196

N300 X.636 Y6.577 Z.2

N302 X.493 Y6.402 Z.138

N304 X.398 Y6.263 Z.092

N306 X.327 Y6.11 Z.046

N308 X.282 Y5.948 Z0.

N310 G2 X-.263 Y4.3 I-6.409 J1.209

N312 G3 X-.191 Y2.606 I2.55 J-.74

N314 G3 X1.966 Y-.012 I4.91 J1.848

N316 G3 X3.688 Y-.772 I3.132 J4.765

N318 G3 X4.54 Y-.483 I.1 J1.106

N320 G1 X4.704 Y-.369

N322 X6.015 Y.549

N324 X6.144 Y.657 Z.013

N326 X6.253 Y.784 Z.025

N328 X6.339 Y.929 Z.038

N330 X6.68 Y1.625 Z.097

N332 X6.766 Y1.769 Z.11

N334 X6.875 Y1.897 Z.122

N336 X7.004 Y2.005 Z.135

N338 X7.713 Y2.501 Z.2

N340 X8.175 Y2.825 Z.152

N342 X8.321 Y2.91 Z.138

N344 X8.478 Y2.969 Z.123

N346 X8.644 Y3. Z.109

N348 X9.414 Y3.082 Z.043

N350 X9.579 Y3.114 Z.029

N352 X9.737 Y3.173 Z.014

N354 X9.882 Y3.257 Z0.

N356 X10.128 Y3.429

N358 G3 X11.625 Y4.507 I-18.395 J27.136

N360 G3 X12.471 Y6.725 I-2.321 J2.156

N362 G3 X11.812 Y7.541 I-.992 J-.127

N364 G2 X10.72 Y8.036 I2.33 J6.601

N366 G1 X10.567 Y8.106 Z.014

N368 X10.404 Y8.148 Z.028

N370 X10.237 Y8.163 Z.042

N372 X9.61 Y8.167 Z.095

N374 X9.416 Y8.187 Z.111

N376 X9.23 Y8.244 Z.128

N378 X9.058 Y8.337 Z.144

N492 G0 Z50.

N494 M5

N496 T0 M6

N498 G91 G28 Z0

N500 G28 Y0

N502 G90

N504 G17

N506 M99

%

5 axes pour Heid 426

0 BEGIN PGM TEST-ED-SORALUCE MM

1 BLK FORM 0.1 Z X+0 Y+0 Z+0

2 BLK FORM 0.2 X+0 Y+0 Z+0

3 ; POST-PRO FICAM

4 ; MACHINE - SORALUCE FBF 59 5AXES

5 ; DESSIN MASTERCAM - TEST-ED-SORALUCE

6 ; PROG-CN DU 02-12-10 A 15:38

7 ; LISTE DES OUTILS UTILISES

8 ; T34 OUTIL EBAUCHE FRAISE 2 TAILLES DIAM=61. 4 DENTS ARS

9 ; FIN DE LISTE DES OUTILS

10 FN 0: Q80=0 ; Numero d'origine programme

11 L R0 FMAX

12 ; *GROUPE D'USINAGE-2*

13 ; T34 OUTIL EBAUCHE FRAISE 2 TAILLES DIAM=61. 4 DENTS ARS

14 ; CORRECTION ORDINATEUR GAUCHE

15 ; SUREP R 0. SUREP Z 0.

16 CYCL DEF 399 CHANGE OUTIL ~

Q389=34 ; OUTIL DEMANDE

17 TOOL CALL 34 Y S1500

18 CYCL DEF 19.0 PLAN D'USINAGE

19 CYCL DEF 19.1 B+0 C+0

20 CYCL DEF 19.0 PLAN D'USINAGE

21 CYCL DEF 19.1

22 L X-2000 Y+0 Z+0 FMAX M92

23 CYCL DEF 397 AUTOMATIC TETE ~

24 Q399=+0 ;Degre art verticale ~

25 Q398=+0 ;Degre art diagonale

26 M10

27 L A+0 F500

28 CYCL DEF 10.0 ROTATION

29 CYCL DEF 10.1 ROT+0

30 CYCL DEF 7.0 POINT ZERO

31 CYCL DEF 7.1 #0

32 CYCL DEF 7.0 POINT ZERO

33 CYCL DEF 7.1 #Q80

34 M3

35 L X-3,9 Z+67,7 Y+50 FMAX M3

36 L Y+2 FMAX

37 L Y-10 F2000

38 L Z+61,6

39 CC X-10 Z+61,6

40 C X-10 Z+55,5 DR+

41 L X-100

42 CC X-100 Z+25

43 C X-130,5 Z+25 DR-

44 L Z-25

45 CC X-100 Z-25

46 C X-100 Z-55,5 DR-

47 L X+100

48 CC X+100 Z-25

49 C X+130,5 Z-25 DR-

50 L Z+12,012

51 CC X+100 Z+12,012

52 C X+116,611 Z+37,591 DR-

53 L X+89,035 Z+55,5

54 L X-10

55 CC X-10 Z+61,6

56 C X-16,1 Z+61,6 DR+

57 L Z+67,7

58 L Y+50 FMAX

59 ;

60 ; CORRECTION AUCUNE

61 ; SUREP Z 0.

62 L X-167,1 Z+0 FMAX

63 L Y+2 FMAX

64 L Y+0 F2000

65 L X+167,1

66 L Y+50 FMAX

67 ;

68 ; CORRECTION AUCUNE

69 ; SUREP Z 0.

70 M11

71 CYCL DEF 19.0 PLAN D'USINAGE

72 CYCL DEF 19.1 B+0 C+0

73 CYCL DEF 19.0 PLAN D'USINAGE

74 CYCL DEF 19.1

75 L X-2000 Y+0 Z+0 FMAX M92

76 CYCL DEF 10.0 ROTATION

77 CYCL DEF 10.1 ROT+0

78 CYCL DEF 7.0 POINT ZERO

79 CYCL DEF 7.1 #0

80 CYCL DEF 7.0 POINT ZERO

81 CYCL DEF 7.1 #Q80

82 CYCL DEF 397 AUTOMATIC TETE ~

83 Q399=+22,5 ;Degre art verticale ~

84 Q398=+0 ;Degre art diagonale

85 M11

86 L A+90 F500

87 CYCL DEF 10.0 ROTATION

88 CYCL DEF 10.1 ROT-90

89 CYCL DEF 19.0 PLAN D'USINAGE

90 CYCL DEF 19.1 B+0 C+22,5

91 M11

92 M3

93 L X-167,1 Z+9,241 Y+50 FMAX

94 L Y+5,827 FMAX

95 L Y+3,827 F2000

96 L X+136,6

97 CC X+136,6 Z+13,858

98 C X+136,6 Z+18,476 DR-

99 L X-167,1

100 L Y+50 FMAX

101 ;

102 ; CORRECTION AUCUNE

103 ; SUREP Z 0.

104 M11

105 CYCL DEF 19.0 PLAN D'USINAGE

106 CYCL DEF 19.1 B+0 C+0

107 CYCL DEF 19.0 PLAN D'USINAGE

108 CYCL DEF 19.1

109 L X-2000 Y+0 Z+0 FMAX M92

110 CYCL DEF 10.0 ROTATION

111 CYCL DEF 10.1 ROT+0

112 CYCL DEF 7.0 POINT ZERO

113 CYCL DEF 7.1 #0

114 CYCL DEF 7.0 POINT ZERO

115 CYCL DEF 7.1 #Q80

116 CYCL DEF 397 AUTOMATIC TETE ~

117 Q399=+45 ;Degre art verticale ~

118 Q398=+0 ;Degre art diagonale

119 M11

120 L A+237 F500

121 CYCL DEF 10.0 ROTATION

122 CYCL DEF 10.1 ROT-90

123 CYCL DEF 19.0 PLAN D'USINAGE

124 CYCL DEF 19.1 B+0 C+45

125 M11

126 M3

127 L X-46,527 Z+38,566 Y+50 FMAX

128 L Y+40,564 FMAX

129 L Y+38,564 F2000

130 L X+124,092

131 CC X+124,092 Z+45,635

132 C X+124,092 Z+52,704 DR-

133 L X-31,133

134 L Y+50 FMAX

135 ;

136 ; CORRECTION AUCUNE

137 ; SUREP Z 0.

138 M11

139 CYCL DEF 19.0 PLAN D'USINAGE

140 CYCL DEF 19.1 B+0 C+0

141 CYCL DEF 19.0 PLAN D'USINAGE

142 CYCL DEF 19.1

143 L X-2000 Y+0 Z+0 FMAX M92

144 CYCL DEF 10.0 ROTATION

145 CYCL DEF 10.1 ROT+0

146 CYCL DEF 7.0 POINT ZERO

147 CYCL DEF 7.1 #0

148 CYCL DEF 7.0 POINT ZERO

149 CYCL DEF 7.1 #Q80

150 CYCL DEF 397 AUTOMATIC TETE ~

151 Q399=+45 ;Degre art verticale ~

152 Q398=+0 ;Degre art diagonale

153 M11

154 L A+90 F500

155 CYCL DEF 10.0 ROTATION

156 CYCL DEF 10.1 ROT-90

157 CYCL DEF 19.0 PLAN D'USINAGE

158 CYCL DEF 19.1 B+0 C+45

159 M11

160 M3

161 L X-31,133 Z+52,704 Y+60,607 FMAX

162 L X-167,1 Z+15,609 FMAX

163 L Y+12,607 FMAX

164 L Y+10,607 F2000

165 L X+136,6

166 CC X+136,6 Z+20,178

167 C X+136,6 Z+24,747 DR-

168 L X-167,1

169 L Y+60,607 FMAX

170 STOP M5

171 CYCL DEF 7.0 POINT ZERO

172 CYCL DEF 7.1 #0

173 CYCL DEF 7.0 POINT ZERO

174 CYCL DEF 7.1 #Q80

175 CYCL DEF 19.0 PLAN D'USINAGE

176 CYCL DEF 19.1 B+0 C+0

177 CYCL DEF 19.0 PLAN D'USINAGE

178 CYCL DEF 19.1

179 L X-2000 Y+0 Z+0 FMAX M92

180 CYCL DEF 397 AUTOMATIC TETE ~

181 Q399=+0 ;Degre art verticale ~

182 Q398=+0 ;Degre art diagonale

183 M10

184 L A+0 F500

185 M30

186 END PGM TEST-ED-SORALUCE MM

Siemen 840D pour application Laser

%_N_TEST_11_MPF

;$PATH=/_N_WKS_DIR/_N_ROTOR_WPD

; CAM Tecno Nbr: BALLIU 1

; Groupe d'usinages-1

; Groupe Machine-1

; Customer Nbr :

; Powder: WC-3D

; Created on 02/10/12 AT 5:06 PM

G0 G90 G53 Z=$MA_POS_LIMIT_PLUS[Z]

G90 G17 G54 G0

FGROUP (X,Y,Z,A_2,B_2)

M08 M64 ; COOLING ON,CROSSJET ON

S3=1 M80 ; LASER POWER LOW

M86 ; EXTERNAL MODE ON

SOFT

FFWON

G641 ADIS=0.5

TRANS X0. Y-476. Z-275.

G0 A_2=180. B_2=-75.

X-295.22 Y0.

Z204.99

M0

FGROUP (X,Y,Z,A_2,B_2)

M50 M13 M62 ; EXHAUST ON, RED POINTING LASER OFF, GAZ 2 ON

H25 M94 ; POWDER FEED RATE WAY 1 ON

H10 M96 ; INTENSITY MIXER 1

M13 ; RED POINTING LASER OFF

M90 ; POWDER FEEDER 1 ON

G04 F12 ; WAITING POWDER

G1 F1500.

M10 G04 F0.1

S3=1 M80 ; LASER POWER LOW

G0 Z204.99 A_2=180. B_2=-75.

S3=1 M80

G0 Z106.99 A_2=180. B_2=-75.

S3=50 M80 ; LASER POWER HIGH

G01 G93 G642 F750. Z104.99

F412.93 A_2=188.33

F393.1 A_2=197.09

F378.24 A_2=206.18

F368.33 A_2=215.53

F363.37 A_2=225.

F363.37 A_2=234.47

F368.33 A_2=243.82

F378.24 A_2=252.91

F393.1 A_2=261.67

F412.93 A_2=270.

F412.93 A_2=278.33

F393.1 A_2=287.09

F378.24 A_2=296.18

F368.33 A_2=305.53

F363.37 A_2=315.

F363.37 A_2=324.47

F368.33 A_2=333.82

F378.24 A_2=342.91

F393.1 A_2=351.67

F412.93 A_2=360.

F412.93 A_2=368.33

F393.1 A_2=377.09

F378.24 A_2=386.18

F368.33 A_2=395.53

F363.37 A_2=405.

F363.37 A_2=414.47

F368.33 A_2=423.82

F378.24 A_2=432.91

F393.1 A_2=441.67

F412.93 A_2=450.

F412.93 A_2=458.33

F393.1 A_2=467.09

F378.24 A_2=476.18

F368.33 A_2=485.53

F363.37 A_2=495.

F363.37 A_2=504.47

F368.33 A_2=513.82

F378.24 A_2=522.91

F393.1 A_2=531.67

F412.93 A_2=540.

F413. X-295.29 A_2=548.33

F393.48 X-295.37 A_2=557.09

F378.9 X-295.44 A_2=566.18

F369.26 X-295.52 A_2=575.53

F364.57 X-295.59 A_2=585.

F364.85 X-295.66 A_2=594.47

F370.11 X-295.74 A_2=603.82

F380.36 X-295.81 A_2=612.91

F395.61 X-295.89 A_2=621.67

F415.87 X-295.96 A_2=630.

F416.19 X-296.04 A_2=638.33

F396.53 X-296.11 A_2=647.09

F381.83 X-296.18 A_2=656.18

F372.12 X-296.26 A_2=665.53

F367.4 X-296.33 A_2=675.

F367.69 X-296.41 A_2=684.47

F372.99 X-296.48 A_2=693.82

F383.31 X-296.55 A_2=702.91

F398.69 X-296.63 A_2=711.67

F419.11 X-296.7 A_2=720.

F419.44 X-296.78 A_2=728.33

F399.62 X-296.85 A_2=737.09

F384.81 X-296.92 A_2=746.18

F375.03 X-297. A_2=755.53

F370.27 X-297.07 A_2=765.

F370.56 X-297.15 A_2=774.47

F375.91 X-297.22 A_2=783.82

F386.32 X-297.3 A_2=792.91

F401.81 X-297.37 A_2=801.67

F422.4 X-297.44 A_2=810.

F422.73 X-297.52 A_2=818.33

F402.76 X-297.59 A_2=827.09

F387.84 X-297.67 A_2=836.18

F377.98 X-297.74 A_2=845.53

F373.19 X-297.81 A_2=855.

F373.48 X-297.89 A_2=864.47

F378.87 X-297.96 A_2=873.82

F389.37 X-298.04 A_2=882.91

F404.99 X-298.11 A_2=891.67

F425.74 X-298.18 A_2=900.

F426.08 X-298.26 A_2=908.33

F405.95 X-298.33 A_2=917.09

F390.91 X-298.41 A_2=926.18

F380.98 X-298.48 A_2=935.53

F376.15 X-298.56 A_2=945.

F376.45 X-298.63 A_2=954.47

F381.89 X-298.7 A_2=963.82

F392.47 X-298.78 A_2=972.91

F408.21 X-298.85 A_2=981.67

F429.14 X-298.93 A_2=990.

F429.48 X-299. A_2=998.33

F409.19 X-299.07 A_2=1007.09